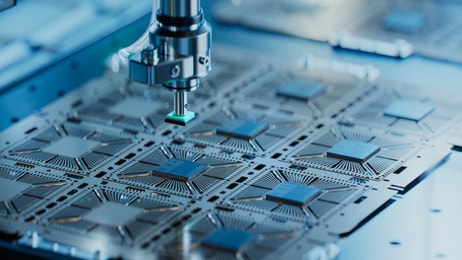

US unveils $1.4bn boost for semiconductor innovation

The US Department of Commerce (DOC) has unveiled a $1.4bn programme to accelerate the development of advanced packaging for semiconductors, part of its CHIPS for America initiative.

Under the CHIPS National Advanced Packaging Manufacturing Program, $300m will go to Absolics Inc., Applied Materials Inc. and Arizona State University for research into advanced substrates and materials.

“These investments are a key milestone as we build an ecosystem that supports modern semiconductor manufacturing in the United States,” said Secretary of Commerce Gina Raimondo in a statement.

... to continue reading you must be subscribed