Safety first: 10 tips for cylinder valve safety

Compressed gas cylinders are commonly used in various industries and applications, but they can present significant hazards if not handled and used properly. Cylinder valves control the flow of gas from a pressurised cylinder.

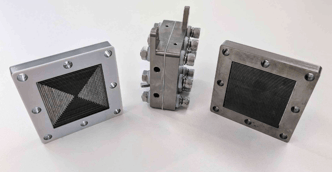

In addition to preventing compressed gases from escaping unintentionally, cylinder valves are usually incorporated with safety features such as pressure relief valves, which prevent over-pressurisation of the cylinder. Valves fitted with residual pressure devices (RPDs) help to retain a minimum level of gas inside a cylinder to minimise contamination risk and ensure supply integrity.

Cylinder valves must be capable of storing gas mixtures at increasingly higher pressures because many industrial and commercial applications require increasingly higher consignment levels for ease and cost-effective transportation, storage and use.

In the medical industry, for example, oxygen is typically stored in cylinders at pressures of 2,000 to 3,000 psi 200 to 300 bar (around 4200 psi), while in the welding industry, gases such as argon, helium oxygen and nitrogen are often stored at 300 bar.

... to continue reading you must be subscribed