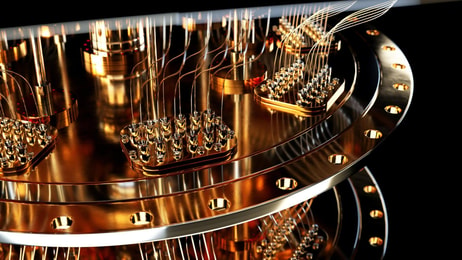

INOX and IISc to launch quantum computing lab for tech advancements

INOX Group will set up a new quantum materials lab at the Indian Institute of Science (IISc) to support advanced semiconductor and quantum technology developments.

The plans were confirmed with a signed Memorandum of Understanding (MoU) between INOX and IISc. The lab will be based the IISc’s Centre for Nano Science and Engineering facility.

As part of the project, the duo will build an indigenous Molecular Beam Epitaxy (MBE) unit, a highly specialised piece of equipment for thin-film deposition.

With its efforts, the duo hope to prevent importing semiconductor and quantum computing technology at high costs. It also aims to to develop a strong workforce and will offer opportunities to undergraduates.

... to continue reading you must be subscribed