Europe approves €350m for synthetic aviation fuels project

The European Commission has approved under EU State aid rules a €350m German measure to support Concrete Chemicals in the production of synthetic aviation fuels.

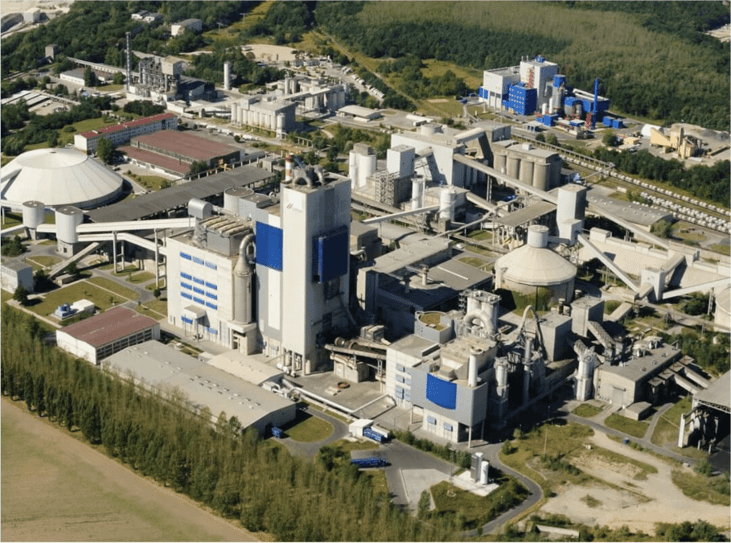

The project will use electricity, renewable hydrogen, and biogenic carbon dioxide (CO2) captured from a cement plant and integrate different technologies such as electrolysers and complex chemical reactors, reverse water-gas shift and Fischer-Tropsch (FT) synthesis.

Partners include renewable energy company Enertrag, global building materials manufacturer Cemex and Sasol ecoFT, a leader in the development and application of FT technology.

Power-to-Liquid (PtL) kerosene produced by the project will qualify as renewable fuel of non-biological origin (RFNBO) as the energy content will come from renewable sources.

... to continue reading you must be subscribed