Europe approves €128m aid for SSAB steel decarbonisation

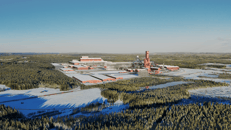

The European Commission has approved a €128m Swedish measure to support SSAB in decarbonising its steel production using renewable hydrogen.

The state aid will take the form of a direct grant and support the accelerated transition to an electric steel mill through the installation of an electric arc furnace (EAF), equipment for secondary metallurgy and a caster.

The EAF will operate using steel scrap and direct reduced iron (DRI) produced using renewable hydrogen. The electric steel mill will have a capacity of 2.5 million tonnes of green slabs per year.

The measure, under the Just Transition Fund, will contribute to the achievement of the European Green Deal and the Green Deal Industrial Plan targets, while also helping to end dependence on Russian fossil fuels and accelerate the green transition, in line with the REPowerEU Plan.

... to continue reading you must be subscribed