Argon playing a key role in AM’s future

Reproducible quality of powder-metal 3D printed parts is essential for advanced aerospace, automotive and medical applications. Yet aluminum and titanium alloys are extremely sensitive to oxygen and humidity.

Controlling these inside the 3D process chamber helps avoid any negative impact on final mechanical properties such as tensile strength and fatigue resistance. It also avoids discoloration and surface defects.

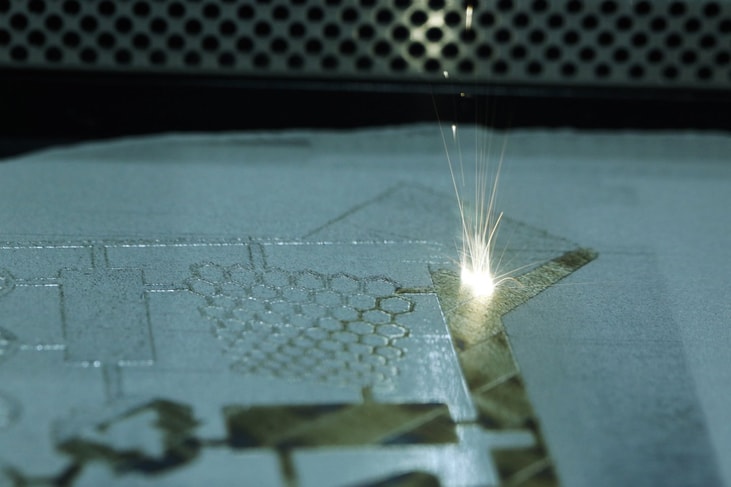

There are several different basic methods of metal additive manufacturing but one of the most common uses a powder bed that is selectively heated with a laser or an electron beam. These include laser powder bed fusion and EBM.

... to continue reading you must be subscribed