Sungrow wins $4bn China hydrogen and ammonia project bid

Sungrow Hydrogen has won the bidding of China Energy Engineering Corporation’s (CEEC) Songyuan Hydrogen Energy Industrial Park project in Jilin China, which is billed as the world’s largest green hydrogen, ammonia and methanol integrated project.

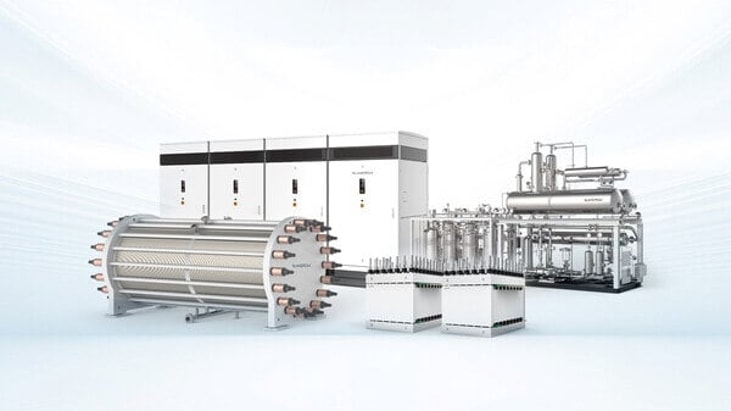

Sungrow Hydrogen’s 1000Nm³/h ALK hydrogen production system will be applied to the $4bn project, which is expected to produce 110,000 tonnes of green hydrogen, 600,000 tonnes of green ammonia and 60,000 tonnes of green methanol.

CEEC’s industrial park project is among the first batch of ‘green and low-carbon advanced’ technology demonstration projects.

The project is the third Sungrow Hydrogen has won in Jilin province and the company plans to implement more projects globally, opening up the path of large-scale production of green hydrogen, ammonia and methanol, and green hydrogen-based chemical industry.

... to continue reading you must be subscribed